-

Why Frymaster?

Life at Frymaster

At Frymaster, innovation starts with our people. We foster a culture built on collaboration, integrity, and continuous improvement. Whether on the factory floor or in the front office, every team member plays a vital role in delivering the quality and performance our customers trust. Join a workplace where ideas are valued, growth is encouraged, and teamwork drives success.

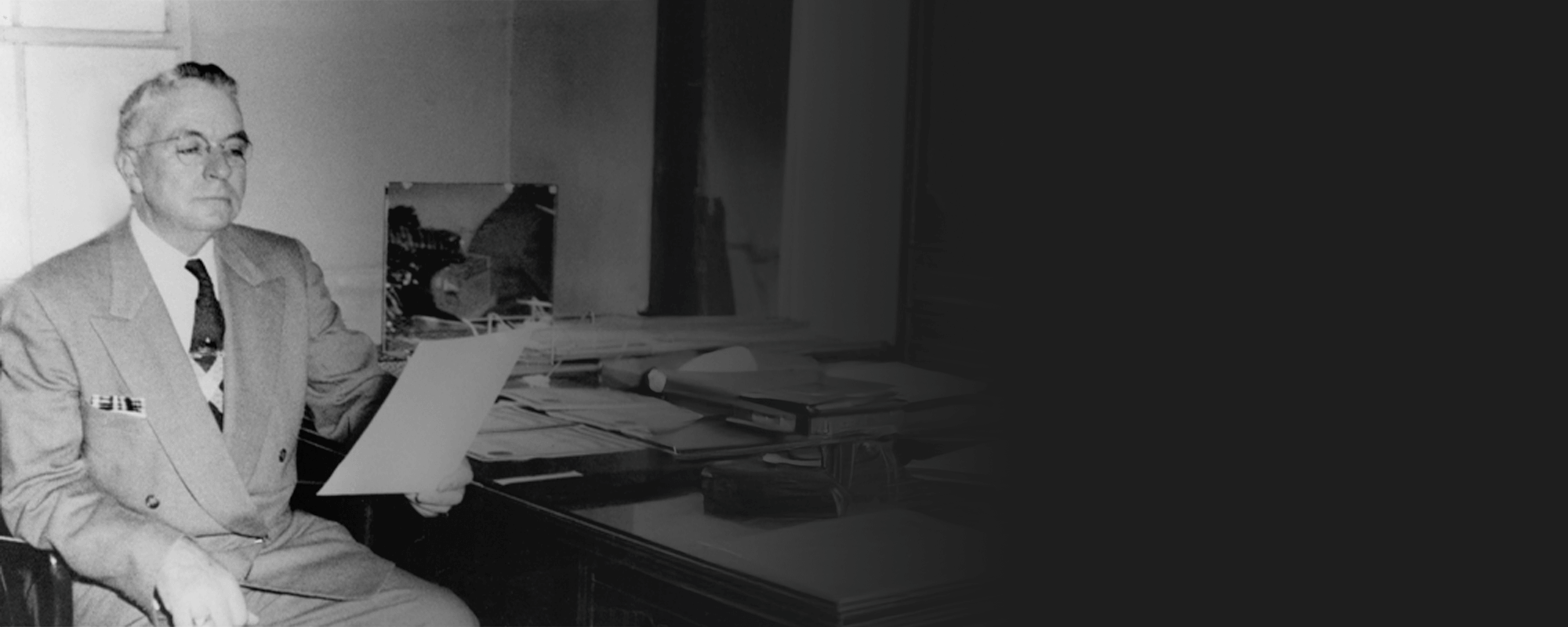

Learn MoreA Legacy of Innovation

For nearly a century, Frymaster has been at the forefront of frying technology, setting the standard for performance, reliability, and efficiency. From our first open-pot fryer to today's cutting-edge solutions, explore the milestones that shaped our journey—and the industry.

Learn MoreSmart Savings, Powerful Performance

Discover the benefits of ENERGY STAR® rated equipment—engineered for efficiency, built for better kitchens.

Learn MoreRooted in Community

Frymaster is proud to support the communities where we live and work. Through volunteer efforts, local partnerships, and charitable initiatives, were committed to making a positive impact beyond the kitchen. From supporting education and local events to giving back through service, community involvement is a core part of who we are.

Learn More-

Frymaster Honored with PRIDE Centric Resources’ 2024 Team Choice – Vendor Award

October 25, 2025October 1, 2025Frymaster is proud to announce it has received the 2024 Team Choice – Vendor Award from PRIDE Centric Resources, a recognition that hig... -

Frymaster Celebrates 90 Years of Innovation with Ribbon-Cutting Ceremony

October 25, 20258/21/2025On August 21, 2025, Frymaster proudly marked 90 years of hard work, innovation, and excellence with a special ribbon-cutting ceremony at its ...

About Frymaster

Founded in 1935 and headquartered in Shreveport, Louisiana, Frymaster has been a leader in innovation for nearly a century. As a premier manufacturer of frying equipment, we are trusted by the biggest names in foodservice worldwide.

Learn More -

-

Products

Product Series

DEAN Fryers

Oil Management

-

Resources

Product Documents

Marketing Material

Equipment Drawings

-

Support

Resources

Service & Warranty

FAQs

- Connect

A legacy of Innovation

For nearly a century, Frymaster has been at the forefront of frying technology, setting the standard for performance, reliability, and efficiency. From our first open pot fryer to today's cutting-edge solutions, explore the milestones that shaped our journey—and the industry.